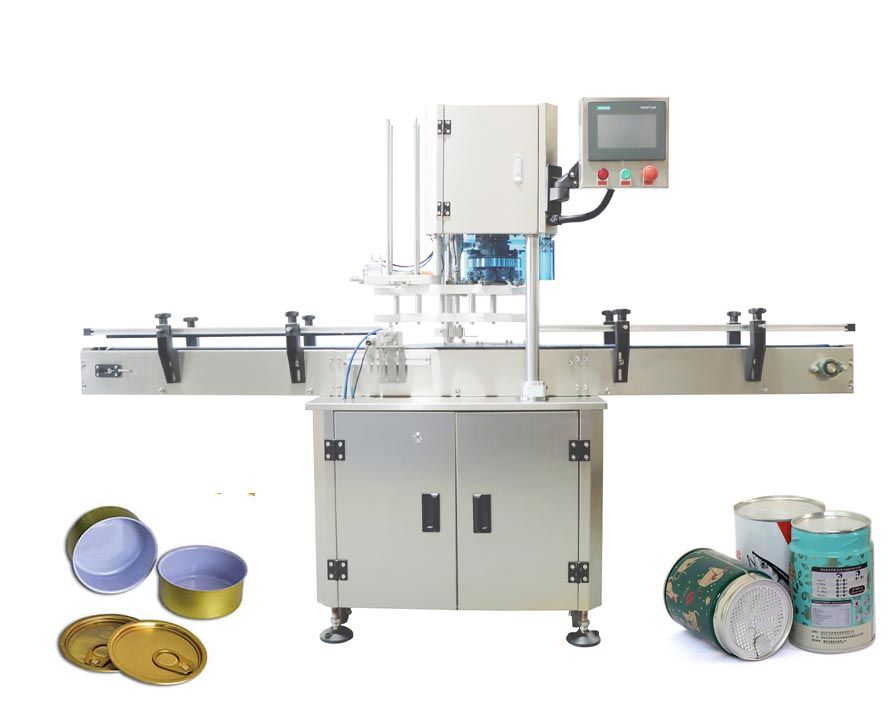

Packaging innovation, particularly through the use of can packaging machines, is revolutionizing product development across various industries. This technology is not only enhancing the efficiency and cost-effectiveness of packaging processes but also driving new product development by enabling creative and practical packaging solutions that meet evolving consumer demands.

Enhancing Efficiency and Cost-Effectiveness

Can packaging machines automate the process of filling, sealing, and labeling cans, significantly increasing production efficiency. This automation reduces the labor required for packaging, lowers operational costs, and minimizes human error, ensuring consistent quality. The high-speed capabilities of these machines allow companies to meet large-scale production demands, making it feasible to introduce new products rapidly. Moreover, the precision of can packaging machines ensures optimal use of materials, reducing waste and contributing to sustainability efforts. The ability to quickly switch between different can sizes and types further enhances flexibility, enabling manufacturers to experiment with various product offerings without extensive downtime or additional costs.

Enabling Creative Packaging Solutions

Innovation in can packaging technology is opening up new possibilities for product presentation. Advanced can packaging machines can handle a variety of can shapes, sizes, and materials, allowing brands to differentiate their products on the shelves. Unique can designs, such as sleek, slim cans or ergonomically shaped containers, can attract consumers’ attention and enhance the overall user experience. In addition, these types of sealing machine can incorporate advanced labeling and printing technologies, enabling high-quality graphics and customized designs. This capability is particularly valuable for limited edition products or promotional campaigns, where eye-catching packaging can significantly boost sales.

Meeting Consumer Demands for Sustainability

Sustainability is a key concern for modern consumers, and can packaging machines are instrumental in addressing this demand. Aluminum cans, commonly used in the packaging industry, are highly recyclable and have a lower environmental impact compared to other packaging materials like plastic. By efficiently producing recyclable cans, packaging machines help companies align with sustainable practices and appeal to eco-conscious consumers. Additionally, innovations in can packaging technology are facilitating the development of lightweight cans that reduce material usage and transportation costs.

Driving New Product Development

The flexibility and capabilities of can packaging machines are driving new product development in various sectors. In the beverage industry, for example, companies are launching an array of new drinks, from craft beers to energy drinks, in uniquely designed cans that appeal to diverse consumer tastes. The ability to quickly adapt production lines for different beverages allows for rapid testing and iteration of new products. In the food industry, can packaging machines are enabling the introduction of ready-to-eat meals, soups, and snacks in convenient, portable cans. This innovation meets the growing demand for on-the-go consumption and long shelf-life products and check out this site www.levapack.com.

Can packaging machines are at the forefront of packaging innovation, driving new product development through enhanced efficiency, creative packaging solutions, and sustainable practices. By automating and optimizing the packaging process, these machines enable companies to introduce innovative products that meet evolving consumer demands and stand out in competitive markets. As technology continues to advance, the potential for further innovation in can packaging and product development remains vast, promising exciting opportunities for brands and consumers alike.